ABOUT US

When Accuracy is No Accident

THE HEART OF ANY GREAT BARREL BEGINS WITH QUALITY STEEL

Our Story

For decades Black Hole Weaponry has operated in the shadows with professionals around the World. We have always produced barrels for the private marksman, hunters, and enthusiasts, but now we are bringing our products out of the shadows and into the heart of America.

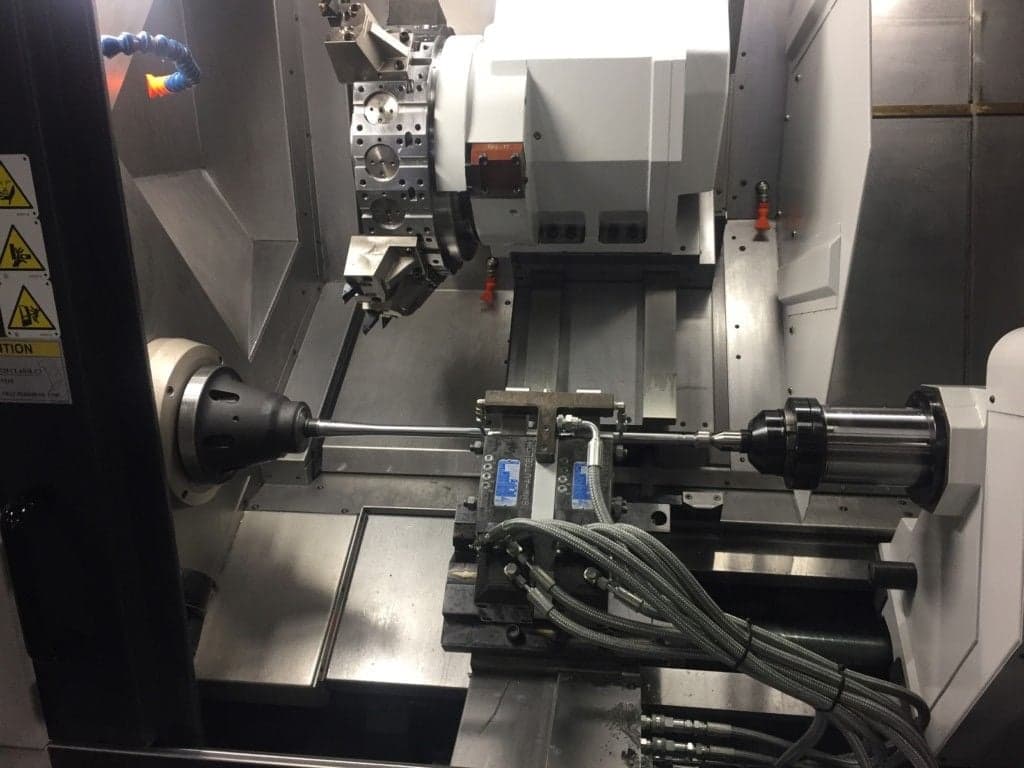

A mixture of the traditional barrel making with a blend of modern science. We utilize the absolute state of the art machining equipment and practices in the production of your barrel. Only the best barrel makers use these processes.

Our Manufacturing Process

Premium Steel Selection

We start with solid stainless steel (BOSS 416R) bar stock imported from Germany. Double stress relieved, polymer quenched, ingot cast, low delta ferrite, DFARS compliant and absolute temperature controlled material.

Precision Preparation

In preparation the bar is trued, squared and inspected for uniformity.

Expert Drilling

Drilling is accomplished with WWII Pratt and Whitney machines and state of the art computer controlled drills, utilizing cutting fluids individually blended for us. The bars are inspected for hole straightness and size before heading onto further processing.

Precision Reaming

Precision reamed on machines of our own design, with precise construction, we hold to a tolerance of .0002".

Advanced Processing

After reaming we employ a few other processes to ensure the most accurate barrel possible.

Polygonal Caudle Rifling

Rifling is accomplished on computer controlled machines where we can control any given twist rate and rifling form. We use our Polygonal Caudle in P3 or P5 rifling known for its accuracy. Once rifled, we subject the barrels to a number of processes to ensure the stability and accuracy we are known for.

We also produce traditional Enfield rifling for those seeking classic rifling patterns with modern precision.

"Accuracy is No Accident"

Choose Black Hole Weaponry for precision barrels made to custom specification.

Explore Our Technology